3D Prototypes: Speed Up Development with High-Quality Rapid Prototyping

The push for innovation in product development is more intense than ever before. Companies are constantly seeking ways to deliver smarter, better-performing products to the market faster. Amid this competitive landscape, 3D Prototypes (3D Prototypen) has become a game-changer. With the rise of high-quality rapid prototyping, businesses are drastically reducing development cycles while maintaining impeccable design precision and functionality.

By harnessing the power of 3D prototyping, organizations can improve the efficiency of their development process, streamline team workflows, and achieve greater accuracy in testing new concepts. This article focuses on the key benefits of leveraging 3D rapid prototyping to simplify the product development process.

What is 3D Prototyping?

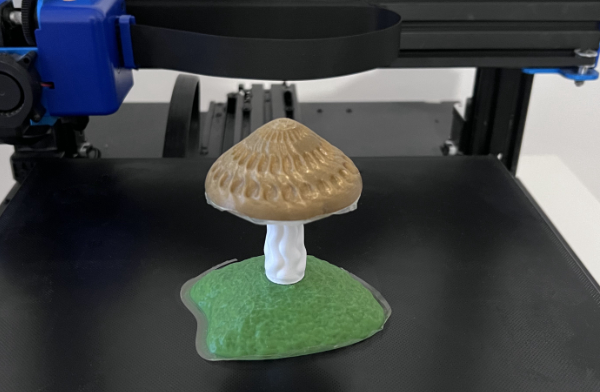

3D prototyping uses advanced additive manufacturing techniques to create digital designs into tangible models. Unlike traditional prototyping methods, it enables faster and more accurate creation of physical prototypes. By using computer-aided design (CAD) technologies, 3D prototyping allows developers to produce intricate designs with exceptional precision. This is particularly beneficial for industries where extensive visual and functional testing is critical.

High-quality rapid prototyping is the process of manufacturing prototypes swiftly and efficiently without compromising on quality. Whether it’s for consumer electronics, medical devices, engineering tools, automotive parts, or architecture mockups, rapid prototyping is the backbone of modern product development.

How Does 3D Prototyping Boost Development?

3D prototyping doesn’t just give product developers the ability to test their ideas. It enhances operational efficiency, offers tangible cost-saving benefits, and ensures that the final product meets customer expectations. Here’s how it delivers faster, smarter results.

1. Accelerates Iterative Design

Prototyping is an essential part of iterative design, where trial and error form the basis of arriving at the perfect product. Traditional methods often extend project timelines due to the slow production of mockups. With 3D prototyping, designs can be fabricated almost immediately after a digital model is completed, enabling designers to test and refine prototypes quickly.

3D prototypes make it easier for development teams to pinpoint potential flaws and implement improvements within hours instead of weeks. The ability to revise designs and create successive iterations keeps projects moving promptly without bottlenecks.

2. Reduces Production Costs

Cost-effectiveness is one of the most substantial advantages of 3D prototyping. Instead of investing hefty sums in mass production and expensive molds during the development phase, businesses can produce prototypes cost-efficiently using additive manufacturing. Furthermore, 3D prototyping eliminates the risk of costly revisions once production has begun by identifying flaws early in the design cycle.

It also minimizes waste. By using only the materials necessary to complete each prototype, 3D printing ensures that resources are optimized during every production phase.

3. Improves Collaboration Between Teams

3D prototyping bridges communication gaps between interdisciplinary teams. It produces physical samples that team members across different departments can analyze, touch, and discuss in real time. This simplifies decision-making processes and brings coherence to the design and strategy discussions.

Having tangible prototypes on hand allows stakeholders, investors, or higher management to visually engage with the product’s progress. This way, they can confidently approve further investment into manufacturing with a clear understanding of what to expect from the final product.

4. Facilitates Better Testing and Validation

The ability to hold a physical model provides a critical advantage when assessing form, fit, and functionality. 3D prototypes exhibit precise details, making them ideal for realistic testing and experimentation. Whether it involves fitting different components together or testing how a prototype will perform under stress, 3D rapid prototyping offers clear, actionable insights.

Proudly powered by WordPress. Theme by Infigo Software.